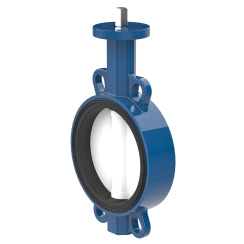

Дисковые затворы поворотные

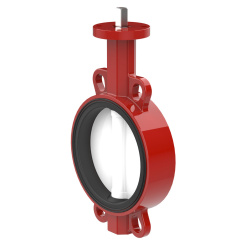

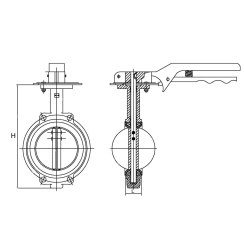

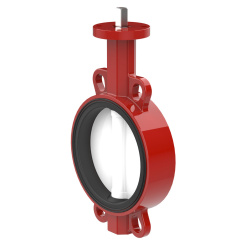

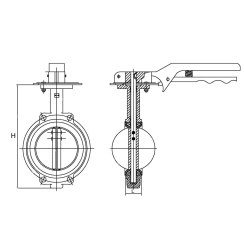

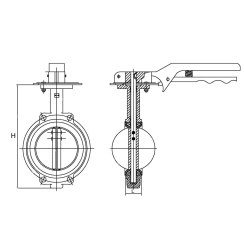

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN100, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN100, PN16. PA300 series handle

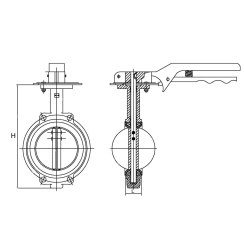

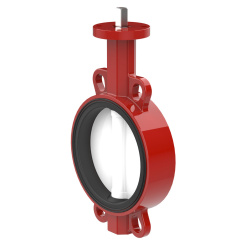

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN100, PN16. PA300 series bare stem

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN100, PN16. PA300 series bare stem

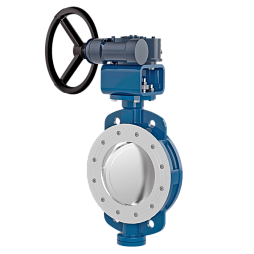

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN100, PN16. PA300 series reducer

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN100, PN16. PA300 series reducer

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN100, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN100, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN100, PN16. PA300 series electric actuator

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN100, PN16. PA300 series electric actuator

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN150, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN150, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN150, PN16. PA300 series bare stem

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN150, PN16. PA300 series bare stem

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN150, PN16. PA300 series reducer

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN150, PN16. PA300 series reducer

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN150, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN150, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN150, PN16. PA300 series electric actuator

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN150, PN16. PA300 series electric actuator

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN50, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN50, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN50, PN16. PA300 series bare stem

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN50, PN16. PA300 series bare stem

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN50, PN16. PA300 series reducer

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN50, PN16. PA300 series reducer

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN50, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN50, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN50, PN16. PA300 series electric actuator

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN50, PN16. PA300 series electric actuator

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN80, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN80, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN80, PN16. PA300 series bare stem

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN80, PN16. PA300 series bare stem

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN80, PN16. PA300 series reducer

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN80, PN16. PA300 series reducer

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN80, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN80, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN80, PN16. PA300 series electric actuator

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN80, PN16. PA300 series electric actuator

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN100, PN16. PA300 series bare stem

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN100, PN16. PA300 series bare stem

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN100, PN16. PA300 series reducer

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN100, PN16. PA300 series reducer

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN100, PN16. PA300 series electric actuator

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN100, PN16. PA300 series electric actuator

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN100, PN16. PA300 series pneumatic actuator

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN100, PN16. PA300 series pneumatic actuator

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN100, PN16. PA300 series reducer

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN100, PN16. PA300 series reducer

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN200, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN200, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN200, PN16. PA300 series bare stem

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN200, PN16. PA300 series bare stem

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN200, PN16. PA300 series reducer

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN200, PN16. PA300 series reducer

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN200, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN200, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN200, PN16. PA300 series electric actuator

Wafer type butterfly valve with steel body and stainless steel disk and EPDM seat, DN200, PN16. PA300 series electric actuator

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN50, PN16. PA300 series bare stem

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN50, PN16. PA300 series bare stem

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN50, PN16. PA300 series electric actuator

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN50, PN16. PA300 series electric actuator

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN50, PN16. PA300 series pneumatic actuator

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN50, PN16. PA300 series pneumatic actuator

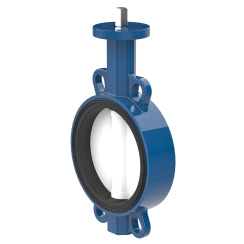

Wafer type lined butterfly valve with steel body and stainless steel disk and PTFE seat, DN50, PN10. PA200 series handle

Wafer type lined butterfly valve with steel body and stainless steel disk and PTFE seat, DN50, PN10. PA200 series handle

Wafer type lined butterfly valve with steel body and stainless steel disk and PTFE seat, DN50, PN10. PA200 series bare stem

Wafer type lined butterfly valve with steel body and stainless steel disk and PTFE seat, DN50, PN10. PA200 series bare stem

Wafer type lined butterfly valve with steel body and stainless steel disk and PTFE seat, DN50, PN10. PA200 series reducer

Wafer type lined butterfly valve with steel body and stainless steel disk and PTFE seat, DN50, PN10. PA200 series reducer

Wafer type butterfly valve and stainless steel disk and NBR seat, DN150, PN16. PA300 series bare stem

Wafer type butterfly valve and stainless steel disk and NBR seat, DN150, PN16. PA300 series bare stem

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN80, PN16. PA300 series bare stem

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN80, PN16. PA300 series bare stem

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN80, PN16. PA300 series electric actuator

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN80, PN16. PA300 series electric actuator

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN80, PN16. PA300 series pneumatic actuator

Wafer type butterfly valve and stainless steel disk and EPDM seat, DN80, PN16. PA300 series pneumatic actuator

Wafer type lined butterfly valve with steel body and stainless steel disk and PTFE seat, DN80, PN10. PA200 series handle

Wafer type lined butterfly valve with steel body and stainless steel disk and PTFE seat, DN80, PN10. PA200 series handle

Wafer type lined butterfly valve with steel body and stainless steel disk and PTFE seat, DN80, PN10. PA200 series bare stem

Wafer type lined butterfly valve with steel body and stainless steel disk and PTFE seat, DN80, PN10. PA200 series bare stem

Wafer type lined butterfly valve with steel body and stainless steel disk and PTFE seat, DN80, PN10. PA200 series reducer

Wafer type lined butterfly valve with steel body and stainless steel disk and PTFE seat, DN80, PN10. PA200 series reducer

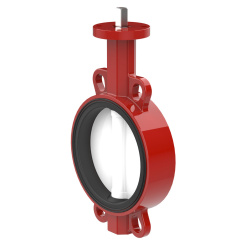

Wafer type butterfly valve with steel body and stainless steel disk and NBR seat, DN100, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and NBR seat, DN100, PN16. PA300 series handle

Wafer type butterfly valve with steel body and stainless steel disk and NBR seat, DN100, PN16. PA300 series bare stem

Wafer type butterfly valve with steel body and stainless steel disk and NBR seat, DN100, PN16. PA300 series bare stem

Wafer type butterfly valve with steel body and stainless steel disk and NBR seat, DN100, PN16. PA300 series reducer

Wafer type butterfly valve with steel body and stainless steel disk and NBR seat, DN100, PN16. PA300 series reducer

Wafer type butterfly valve and stainless steel disk and NBR seat, DN80, PN16. PA300 series bare stem

Wafer type butterfly valve and stainless steel disk and NBR seat, DN80, PN16. PA300 series bare stem

- Принцип действия дисковых поворотных затворов

- Преимущества дисковых затворов

- Недостатки дисковых затворов

- Типы присоединений дисковых затворов

- Управление дисковыми затворами

- Материалы в дисковых затворах

- Производитель дисковых затворов

Принцип действия дисковых поворотных затворов

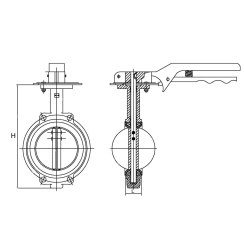

Данный тип трубопроводной арматуры состоит из трех основных элементов: корпус, диск, уплотнение/манжета. Принцип действия поворотных затворов может быть легко описан следующим образом: диск располагается в корпусе изделия перпендикулярно трубопроводу с рабочей средой, а перекрытие потока осуществляется при повороте этого диска на 90° вокруг собственной оси.

Преимущества дисковых затворов

В сравнении с другими видами трубопроводной арматуры затворы имеют следующие преимущества:

- малый вес и габаритные размеры;

- небольшое время закрытия;

- высокая герметичность;

- нет застойных зон;

- простота конструкции и высокая ремонтопригодность;

- относительно невысокая стоимость.

Недостатки дисковых затворов

Наряду с явными преимуществами дисковых затворов нельзя не выделить ряд недостатков, присущих этому типу арматуры:

- высокое гидравлическое сопротивление, т.к. диск находится в проходе корпуса всё время, даже в полностью открытом положении;

- сложность очистки трубопровода механическими устройствами;

- высокий крутящий момент, особенно на больших диаметрах

Типы присоединений дисковых затворов

Затворы дисковые чаще всего производятся в межфланцевом или фланцевом исполнении, реже бывает присоединение под приварку.

Управление дисковыми затворами

Для управления затворами используются:

- рукоятка;

- редуктор;

- электропривод;

- пневмопривод.

Материалы в дисковых затворах

Т.к. в затворе с рабочей средой контактирует только диск и уплотнение, а не корпус изделия, то его рабочие характеристики определяются соответственно только материалами диска и уплотнения.

В зависимости от применяемого материала манжеты выделяют 2 группы дисковых затворов:

- затворы с мягким уплотнением (наиболее распространненый тип);

- затворы с уплотнением металл по металлу.

Уплотнение чаще всего изготавливается из таких материалов, как EPDM, NBR, Viton, PTFE. Материал диска – чугун разных марок, сталь, нержавейка, бронза и т.д. Материал корпуса – чугун, углеродистая, легированная и нержавеющая стали. Общий перечень применяемых материалов очень большой, можно изготовить затвор практически для любой химически сложной среды. Благодаря этому дисковые затворы нашли широкое применение в самых различных отраслях.

Затворы производства ПромАрм с мягким уплотнением представлены сериями ПА200, ПА300, ПА400, ПА600.

Главный недостаток затворов с мягким уплотнением – невысокая максимально допустимая температура рабочей среды и небольшое рабочее давление. Для более сложных условий эксплуатации применяются затворы с уплотнением металл по металлу (серии ПА400, ПА700, ПА900).

Производитель дисковых затворов

С 2001 года компания активно занимается поставками промышленной трубопроводной арматуры. Ориентирование на показатели спроса, современные изменения на рынке и общий интерес клиентов позволили принять решение о том, что настала необходимость в создании собственного производства дисковых поворотных затворов.

Наши сотрудники имеют опыт работы и знания, которые позволили разработать соответствующие технические условия. Производство дисковых поворотных затворов осуществляется строго по ТУ 3700-001-55604618-2013. Арматура используется в различных областях деятельности человека и промышленных направлениях и отраслях:

- Химическая

- Нефтегазовая

- Энергетическая

- Коммунальное хозяйство

- Машиностроение

- Металлургия

Используются изделия также в судостроении. Основное направление, для которого применяются дисковые затворы – запорная и регулирующая арматура. Они способны работать в самых разных по агрессивности средах: абразивы, вода, газ, пар, нефть и нефтепродукты, разнообразная химия.

По желанию клиента дисковые затворы производства ПА могут быть укомплектованы любым типом привода: рукоятка, редуктор, электропривод, пневмопривод. Также устанавливается и другое оборудование, которое будет указано в заявке клиента (например, колонки управления затворами).

Осуществляется последующее сервисное и гарантийное обслуживание.

Купить дисковые затворы

Цены, актуальную информацию по наличию дисковых затворов на складе а также квалифицированную помощь по подбору подходящего вашим задачам изделия Вы можете, позвонив по телефону +7 (8412) 35-07-97 или отправив письмо с заявкой на почту info@promarm.ru

Купить дисковые затворы можно, воспользовавшись формой заказа вверху данной страницы/страницы подраздела (нажав на кнопку "Сделать заказ"). Или перейдите в интересующий раздел и воспользуйтесь фильтром подбора по каталогу продукции / функционалом корзины товаров.